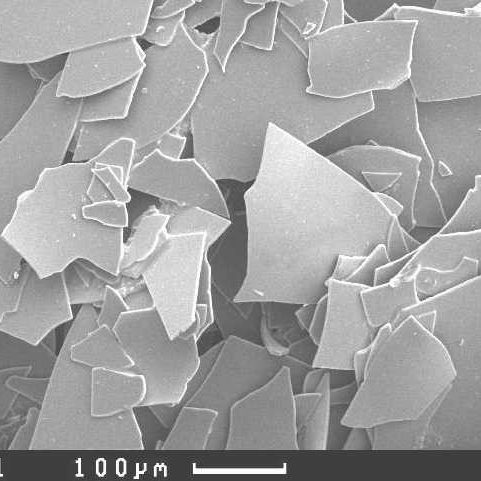

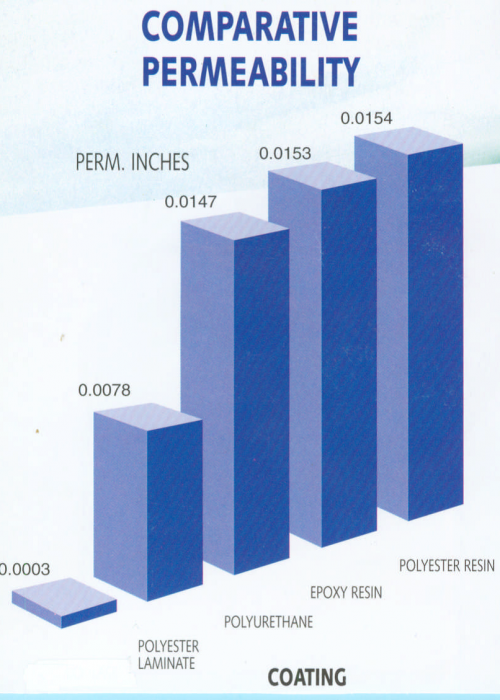

Glassflake technology was developed in the 1970s, the filler that has the shape of a “plate” (flake, flake) ensures that the permeability is reduced enormously. This density ensures that the surface is much better protected against aggressive substances and vapour. In the course of these years, the technology was further optimized. For example, in the last 10 years specific mineral flakes have been made for our coatings; these are very precisely tested by mechanical sieves so that the quality and viscosity is stable

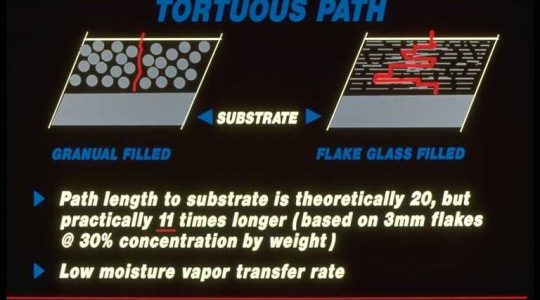

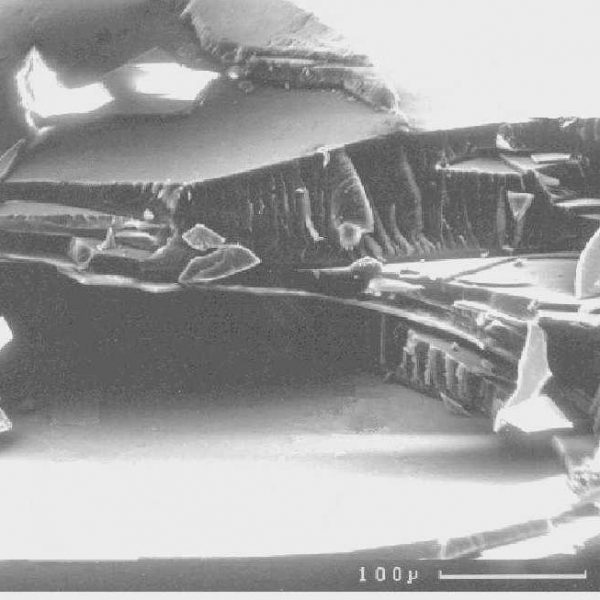

The filling with flakes makes the way to the substrate very difficult to reach and thus the permeability is greatly reduced, which in turn ensures better protection and longer life.

The “flakes” can be based on various basic materials, such as mineral flakes, graphite flakes, copper flakes, Teflon flakes and extremely wear-resistant ceramic flakes.