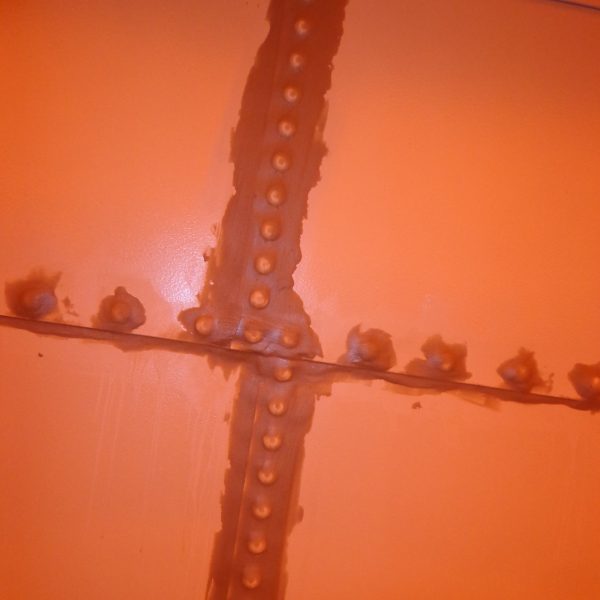

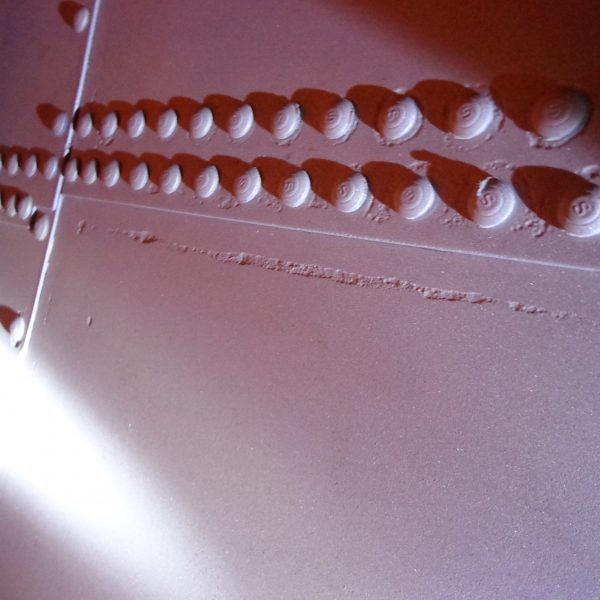

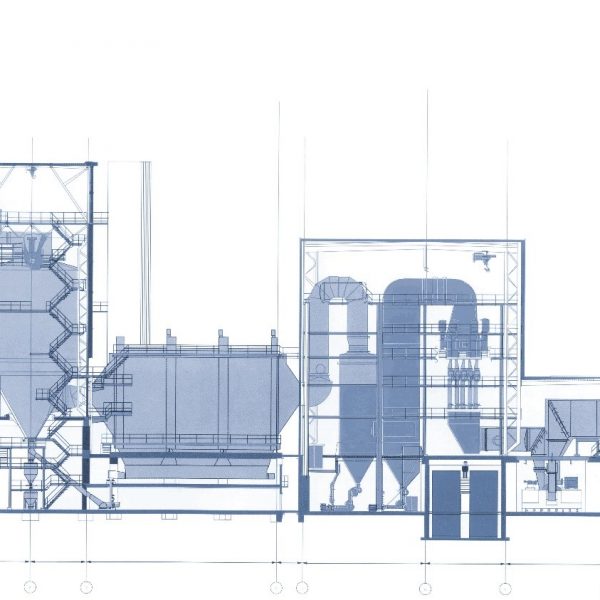

An incineration combustion gas washing installation is common at power plants and waste incineration plants. It introduces various corrosive environmental circumstances in the process plants and combustion gas ducts. Affected plant components are thereby predominantly exposed to aqueous suspensions of solids and dissolved salts, possibly chlorides and sulfates. In addition, various gases are present, e.g. SO2, HCl and NOx. In combination with the high operating temperature, this leads to extremely corrosive conditions for the construction materials.

As a result of different plant designs and operating conditions, practically every gas washing plant has specific chemical, thermal and mechanical stresses of its own. As an experienced company in heavy corrosion protection, GBT specializes in the analysis of such environments and the solution to protect your plant from them.

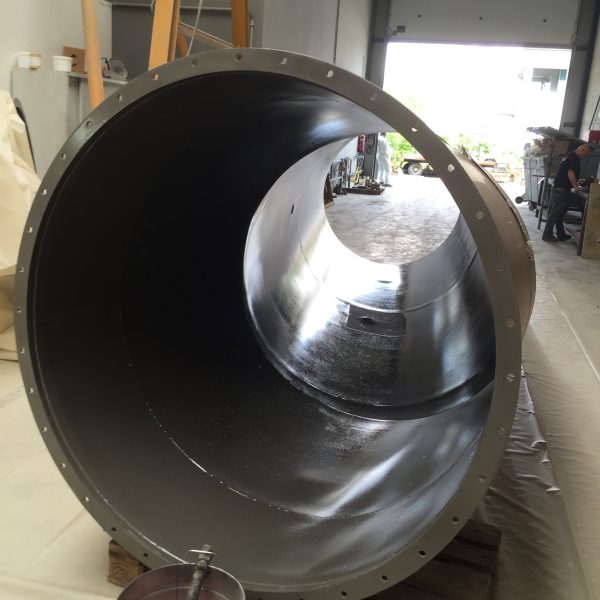

This involves not only the use of highly developed coatings and cladding materials, but also the manufacture of entire components and plant parts by the corresponding specialists of the GBT company.

During combustion gas washing, plant components are exposed to acids and alkalis. The pollutants and dust present in the combustion gas lead to locally high concentrations in areas of low flow, combined with temperature fluctuations. GBT® coating systems address this double burden. Thanks to the large number of variants, they can be tailored very precisely to different applications of use:

- combustion gas ducts, valves

- combustion gas scrubbers, absorbers

- electrostatic precipitators, fabric filters

- chimneys, boiler rooms

- fan housings, impellers

- ash silos, bunkers, chemical tanks

- Heat exchangers

- Cooling water pipes